Differential Locks: Your Tractor's Secret Weapon for Tough Terrain

Ever find your tractor stuck, spinning its wheels in mud or struggling on a steep incline? The solution may lie in understanding and properly utilizing your tractor's differential lock. This instructional guide will equip you with the knowledge to master this crucial feature, maximizing traction, minimizing wear and tear, and ensuring efficient operation. Whether you're a seasoned farmer or a newcomer to agricultural machinery, this guide will provide clear, actionable information to keep your tractor moving. For more on 4-wheel drive tractors, check out this helpful resource: 4WD Tractors.

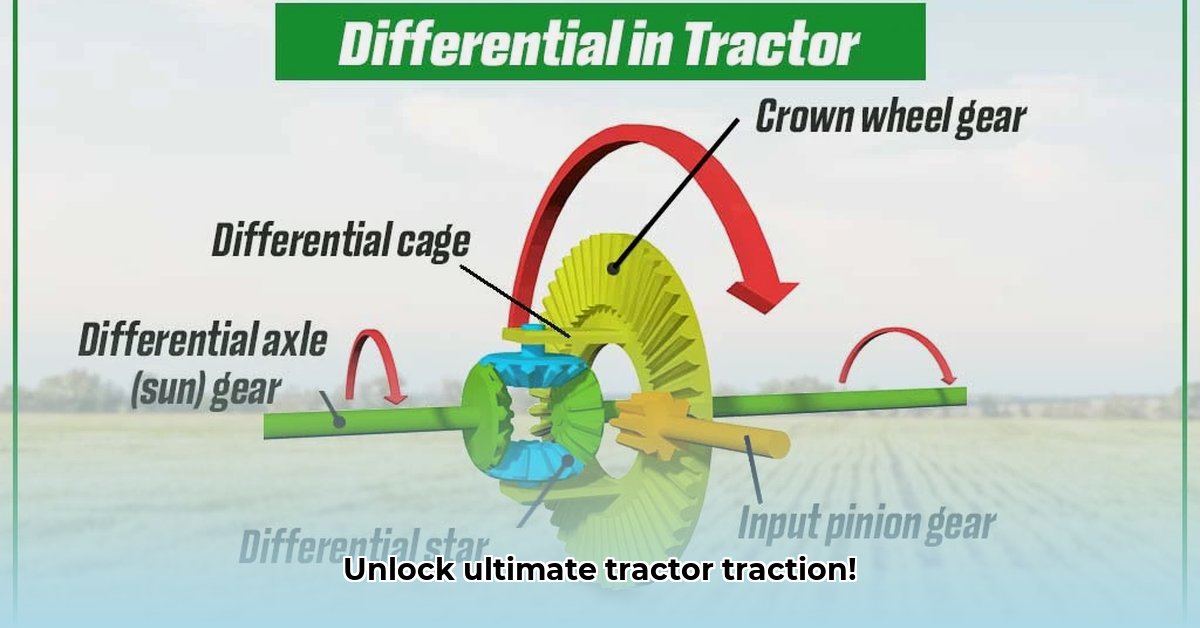

Understanding Tractor Differentials: The Basics of Power Distribution

Tractor differentials allow the wheels on an axle to rotate at different speeds—essential for turning. The inside wheel needs to turn slower than the outside wheel during a turn; otherwise, tire slippage would result. But what happens when one wheel loses traction completely? That's where the differential lock becomes invaluable. It's a mechanical system that connects the wheels on an axle, forcing them to rotate at the same speed, thus maximizing traction in difficult conditions.

How Differential Locks Work: Manual vs. Automatic Systems

Differential locks essentially "lock" the wheels together, preventing one wheel from spinning independently while the other is stuck. There are two primary types:

Manual Differential Locks: These require manual engagement, usually via a lever or button. This provides the operator with complete control but demands attention to proper engagement and disengagement.

Automatic Differential Locks: These systems automatically engage when they detect wheel slippage. While convenient, they may not always be appropriate for every low-traction situation. Understanding their limitations is crucial.

Do you want the added control of a manual lock, or the convenience of an automatic system? The choice depends on your individual needs and farming practices.

When to Use a Differential Lock: Maximizing Traction in Challenging Situations

Engaging the differential lock is not a default setting; it's a tool to be used strategically. Employ it only when necessary to avoid undue wear and tear on your tractor. Common scenarios include:

- Low Traction Conditions: Mud, snow, ice, and loose soil significantly reduce wheel grip. The differential lock evens out power distribution, preventing wheel spin and maximizing traction.

- Steep Inclines: Climbing steep slopes can cause one wheel to lose traction. The lock ensures both wheels pull equally, enhancing stability and preventing slippage.

- Heavy Loads: Towing heavy trailers or equipment puts extra strain on the wheels, increasing the risk of slippage. The differential lock provides the necessary extra traction to handle heavy loads effectively.

- Uneven Terrain: Rocks, ruts, and uneven surfaces create inconsistent wheel contact. The differential lock compensates for these inconsistencies, helping maintain forward momentum.

Remember: using the differential lock on hard, level surfaces is unnecessary and can damage the system. Always consult your tractor's owner's manual for specific guidance. What percentage of your typical farming activities require the use of differential locks?

How to Use a Differential Lock: Step-by-Step Instructions

Manual Differential Lock Engagement:

- Locate the Lever/Button: Refer to your owner's manual for the exact location.

- Engage the Lock: Move the lever or press the button to the "locked" position. You may hear or feel a click confirming engagement.

Manual Differential Lock Disengagement:

- Regain Traction: Ensure you've regained sufficient traction before disengaging.

- Disengage the Lock: Move the lever or press the button to the "unlocked" position.

Automatic Differential Lock: These systems typically engage automatically in low-traction situations, but it's still important to remain aware of your surroundings and monitor their performance.

Safety First: Always consult your tractor's owner's manual for precise instructions on engaging and disengaging the differential lock for your specific model. Ignoring these instructions may result in significant damage or injury. How would you rate the importance of mastering this process?

Maintaining Your Differential Lock: Preventing Future Problems

Regular maintenance is crucial for the longevity and efficient operation of your differential lock.

- Fluid Levels: Periodically check and top off the differential fluid as recommended in your owner's manual. Low fluid levels lead to increased friction and wear.

- Leak Detection: Regularly inspect the differential for leaks. Promptly address any leaks to prevent significant damage and costly repairs.

- Lubrication: Maintain proper lubrication of all components as per the manufacturer's recommendations. This minimizes friction and prolongs the life of the system.

Dr. Emily Carter, Agricultural Engineering Professor at Purdue University, emphasizes: "Preventive maintenance is key to preventing costly repairs and ensuring optimal performance of your tractor's differential lock system. Neglecting regular checks can lead to premature wear and failure."

Long-Term Considerations: Avoiding Overuse and Maximizing Lifespan

While invaluable in tough situations, overuse of the differential lock can shorten its lifespan and reduce fuel efficiency. It increases wear and tear on components, leading to more frequent maintenance and potential repairs. Use it only when necessary; it's a tool for challenging conditions, not routine operation.

Conclusion: Master Your Tractor's Differential for Optimal Performance

Mastering your tractor's differential lock system is essential for efficient and safe operation. Understanding its function, proper usage, and regular maintenance will significantly improve your tractor's performance, extend its lifespan, and ultimately boost your productivity. Always consult your owner's manual for model-specific instructions and safety precautions.

Appendix: Types of Differential Locks

| Feature | Manual Lock | Automatic Lock |

|---|---|---|

| Engagement | Manually controlled | Automatic, based on wheel slip detection |

| Control Precision | High | Moderate |

| Maintenance Complexity | Lower | Higher |

| Wear & Tear | Lower (with proper use) | Higher (potential for overuse) |